Prefabrication: Revolutionizing Modern Homebuilding

For decades, the residential construction industry has been mired in a familiar cycle: long timelines, unpredictable costs, significant waste, and a reliance on on-site labor often battling adverse weather conditions. As the global housing crisis deepens and the need for faster, more affordable, and more sustainable homes becomes critical, this traditional model is proving to be outdated and inefficient. A powerful and transformative solution, however, is not a new invention but a revolutionary approach to an old idea: prefabricated housing. This is the practice of building homes or their major components in a controlled, factory environment and then transporting them to the final building site for assembly. While the concept has existed for a century, a new era of technology, design, and manufacturing has elevated prefabrication from a niche, low-quality option to a sophisticated, scalable solution that is reshaping the entire homebuilding industry. This article will serve as a comprehensive exploration of the new era of prefabricated housing, delving into its core principles, the innovative technologies that are driving its adoption, and the immense economic, environmental, and social benefits it promises to bring to a world in dire need of better, faster, and more sustainable homes.

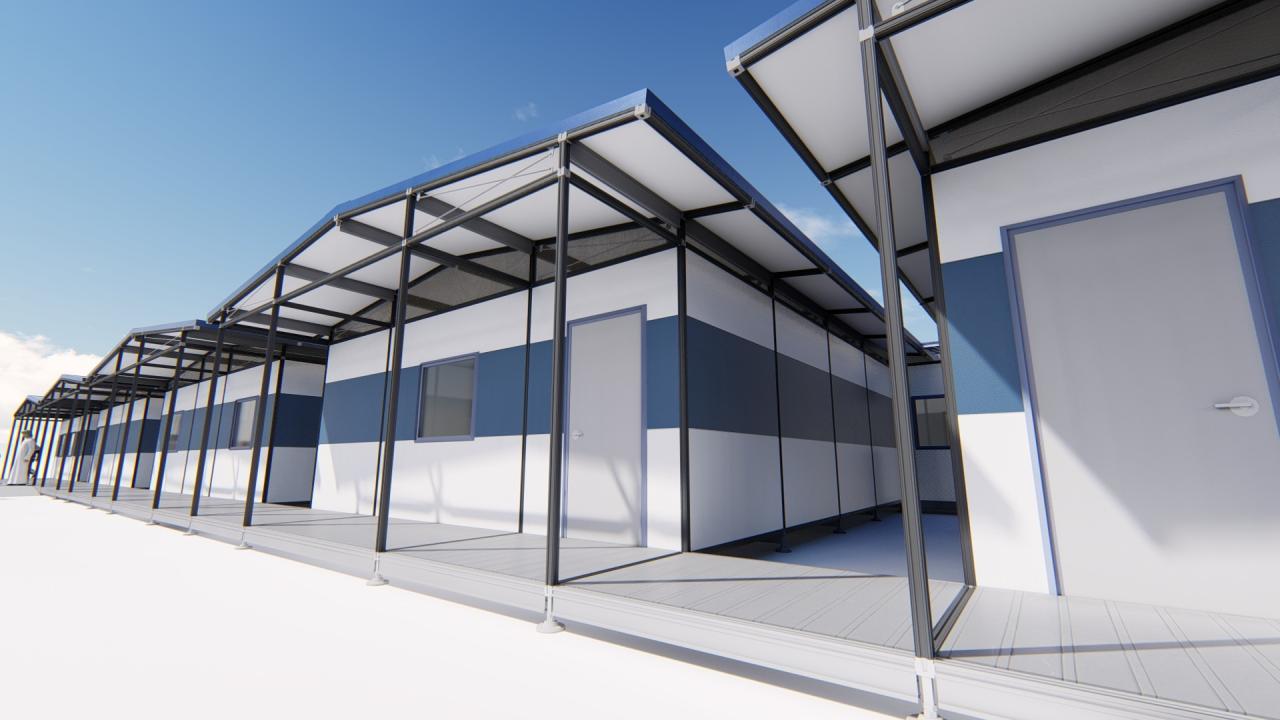

The Foundational Principles of Modern Prefabrication

Modern prefabrication is built on a set of core principles that separate it from the conventional, stick-built construction model. It’s a philosophy that applies the efficiency and precision of manufacturing to the complex process of building a home.

A. Factory-Controlled Quality:

The most significant advantage of prefabrication is the shift to a factory environment. Building homes indoors, in a climate-controlled setting, eliminates delays caused by weather, improves worker safety, and, most importantly, allows for a level of quality control that is impossible to achieve on a traditional construction site. Each component and module can be inspected at every stage of production, ensuring that the final product is built to a higher standard of precision and durability. This results in a home that is stronger, more airtight, and less prone to defects, leading to significant long-term savings on maintenance and energy bills.

B. Accelerated Timelines and Parallel Processes:

In traditional construction, site work (e.g., foundation, utility connections) and building erection happen sequentially. This is a time-consuming process that can take many months. With prefabrication, these processes happen in parallel. While the foundation is being prepared at the building site, the home modules are being simultaneously built in the factory. This overlap can reduce project timelines by 30% to 50%, a major advantage for developers and homeowners who need to get a home to market or move in much faster. The predictability of the timeline is also a key benefit, as it reduces the stress and uncertainty that often accompany a traditional home build.

C. Minimized On-Site Disruption:

A prefabricated home requires far less on-site activity, which means less noise, dust, and traffic congestion in the neighborhood. The assembly of the modules is often a matter of days or a few weeks, not months. This is a significant benefit for projects in densely populated urban or suburban areas, where a long and disruptive construction period can be a major source of conflict with neighbors and local communities. The entire process is quieter, cleaner, and more respectful of the surrounding environment.

The Economic, Environmental, and Social Advantages

The benefits of prefabrication are wide-ranging and address some of the most critical challenges facing the global housing market today.

Economic Benefits

- A. Cost Predictability and Reduction: Because a significant portion of the work is done in a factory, costs are easier to predict and control. Materials can be purchased in bulk, and labor costs are more stable. This reduces the risk of budget overruns, which are common in traditional homebuilding. While the initial cost of a prefabricated home can be higher than a conventional home, the savings on labor, construction time, and long-term energy bills often make it a more affordable option in the long run.

- B. Increased Property Value: Homes that are built to a higher standard of quality and energy efficiency often command a higher price in the real estate market. They are seen as a premium product by consumers who are increasingly prioritizing sustainability and durability. This makes a prefabricated home a more valuable and secure asset in the long run.

- C. A Solution for the Labor Shortage: The construction industry is facing a major labor shortage. Prefabrication, by centralizing a significant portion of the work in a factory, requires fewer on-site workers and creates new, skilled jobs in a controlled, safe environment. This helps to address the labor shortage and provides a more stable career path for construction workers.

Environmental Benefits

- A. Drastic Reduction in Waste: In a factory setting, waste can be meticulously managed and recycled. The standardization of modules reduces material off-cuts, and any excess material can be reused in the next module. This can lead to a reduction in construction waste by up to 90% compared to a traditional building site, making prefabrication one of the most sustainable building methods available.

- B. Energy Efficiency and Lower Carbon Footprint: Prefabricated homes are often designed with a focus on energy efficiency from the very beginning. The precise construction and tight seals of a factory-built module result in superior insulation and reduced air leaks, significantly lowering a home’s long-term energy consumption for heating and cooling. This also lowers the embodied carbon of the home, as less energy is needed to transport materials and power on-site construction.

- C. Material Innovation: The new era of prefabrication is using a wider range of sustainable and innovative materials, from sustainably sourced timber to recycled steel and innovative biomaterials. This allows for a more environmentally responsible home that is also durable and aesthetically pleasing.

Redefining Architectural Aesthetics

Early prefabricated homes were often criticized for their monotonous, cookie-cutter appearance. However, the new era of prefabrication has embraced a new level of architectural sophistication and customization.

- A. The Power of Combination: The beauty of modular design is that a few standardized modules can be combined in an infinite number of ways. By stacking, shifting, and arranging modules, architects can create complex, dynamic, and visually interesting forms. This allows for a high degree of customization and a unique architectural expression for each home, from a multi-story urban townhouse to a sprawling suburban family home.

- B. Seamless Integration with Smart Technology: Modern prefabricated homes are being built as “smart” from the ground up. They can come pre-installed with integrated smart home systems, energy-efficient lighting, and advanced climate control, making the final home not just a structure, but a high-tech living environment that is ready for a connected future.

- C. The Rise of Dwellings-as-a-Service: The business model of prefabrication is also evolving. Companies are now offering a “dwellings-as-a-service” model, where a customer can select a home, customize it, and have it built and installed on their site with a single point of contact. This simplifies the homebuilding process and makes it more accessible to a wider range of consumers.

The Future is Modular

The global housing crisis is one of the most pressing challenges of our time. The demand for housing, particularly in urban areas, is far outstripping the supply. Traditional construction, with its long timelines and high costs, simply cannot keep up. Prefabrication offers a tangible, scalable solution. It can deliver high-quality, affordable housing units at an unprecedented speed, helping to meet the growing demand for urban and suburban living.

The modular approach is also ideal for the future of building in a climate-uncertain world. The high level of quality control and the ability to build with stronger, more durable materials means that a prefabricated home is often more resilient to extreme weather events, from hurricanes and earthquakes to wildfires. This makes it a smart choice for a future that is more volatile and unpredictable.

The journey to a future built on prefabrication will not be easy. It requires a fundamental shift in how developers, architects, and policymakers think about urban development. It requires a willingness to embrace new technologies and new ways of working. But the rewards are immense: more affordable and sustainable homes, a more resilient urban landscape, and a renewed sense of hope that we can solve the global housing crisis and build a better future for everyone.

Conclusion

Prefabricated housing has moved far beyond its humble beginnings. It is no longer a niche or last-resort option but a sophisticated, scalable, and sustainable solution to the most pressing challenges facing the construction industry. By shifting a significant portion of the work from the unpredictability of a building site to the efficiency of a factory, it delivers a superior product in a fraction of the time and with a fraction of the waste. It is a fundamental re-imagining of the entire building process. It’s about leveraging the power of manufacturing principles to create a more resilient, more reliable, and more environmentally friendly built world.

The journey to a future built on prefabrication will not be easy. It requires a willingness to embrace the challenges and the complexities of working with new technologies and new ways of thinking. But the rewards are immense: more affordable and sustainable homes, a more resilient and character-filled urban landscape, and a renewed sense of connection to our past. The era of the disposable, inefficient, and wasteful building is over. The time of the living, evolving, and resilient structure has begun. This is the blueprint for a future that is not just more functional, but also has a soul.